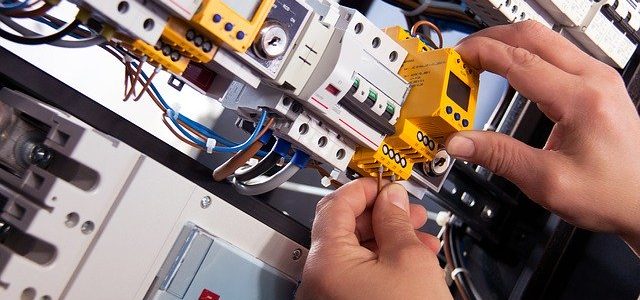

There are companies now whose main goal is to help the scientists and engineers to have functional electronics enclosure as soon as possible. Companies are now making it to a point that they are always improving and expanding their capabilities that effectively aligns with the customers what they want to achieve in their respective industries.

In these recent years, because of the cost of the metals being used for electronics enclosures, there has been increasing number of people requesting for plastic parts or components. Companies are now stocking different plastic materials that can be machined in just 2-3 days. Its either alone or part of the overall enclosure assembly. In this article, we will show you how these companies uses plastics as part of their enclosure assembly.

Tips for Using Plastics in Enclosures

Acrylic and acetal primarily are included in 3-axis milled, they can be made either on CNC router or mill. In addition to this, this only menas that countersinks, counterbores, pockets, or any other 3-axis milled feature may be added.

The cutouts that were being made on the acrylic and acetal are being milled and is also subjected to a minimum corner radius at it gets bigger once the thickness increases. This factor should be carefully considered when you are mounting rectangular or squares components in the cutouts of the plastic. Once these said constraints began to be a problem, you should approach the companies manufacturing plastic accessory to help you with your goal.

When you are attaching plastics through the threaded fasteners, it is advisable that the utilisation of holes inside the plastic with bolts, nuts washers instead of threading them inside the plastic. Be careful not to strip the threads when you are installing fasteners.

In case that the user will be utilizing the RF sensor technology or antennas inside the enclosure, (Wi-Fi), it is suggested to use the acrylic panels or acetal panels. Because sheet metals can attenuate signals.

The acrylic plastic can be etched during the milling process including the silkscreened graphics can also be applied. Both of the techniques can give you very attractive results.

Both plastics (acrylic and acetal) can be effectively mounted flush on the electronics enclosure surfaces. This is achieved by carefully milling the edges of the plastic in order to create a boss that matches the cutout of the enclosure face. Fastening is done through the threaded fasteners or structural tapes.

The Use of Acrylic in Your Enclosure:

Most of the design engineers utilize acrylic for its good transparency, however they are also using the same material for other purposes such as electrical insulation or RF transparency. Most often that not, they use to to generate viewing windows for the enclosure and also to get certain aesthetical goals. For example, Linus Sebastian, one of YouTube’s most popular technology reviewers wants a window for his custom desktop electrical box. So he opted to use an optically clear cast acrylic sheet that has 7/32” in thickness (not stocked), 15” x 15.5”and bolted on over studs.